Nejilock has over 20 years of experience in Electroluminescent (EL) Light Technology. We have assisted many companies in setting up their own EL Factory. Your search ends here for expert guidance in crafting your Electroluminescent Light Panels!

Our comprehensive content will guide you through diverse techniques for producing EL Light Panels, detailing the necessary machinery and equipment, essential design principles, and intricate production procedures.

Discover the secrets behind Silkscreen Printed EL, Spray Painted EL, and Roll-to-Roll Slot-die-coated EL methods. Learn to design ink layers effectively and explore the machinery, inks, substrates, and inverters essential for creating stunning EL Lights.

Electroluminescent Light Technology is a non-thermal generation of light resulting from the application of an electric field to a substance.

The EL Light Panel is created by the following steps:

There are a few ways to make Electroluminescent Light Panels. We will explain them one by one, continue reading, or contact us for more information.

Flexible, made of Plastic.

Can be twisted, bent & cut into any shapes & sizes.

UV & Water Resistant.

Main Power or Battery Operated.

Low power consumption.

High visibility.

Light weight.

Non glaring.

Portable and easy to install.

In Electroluminescent Light Technology, the Screen Printing is the most commonly used method of making the EL Light Panels. The reasons must be the availability of skilled workers, machinery, and supporting industries.

The process is similar to printing posters or textiles, except EL requires understanding the function of different ink layers and handling printing inks with bigger particle sizes.

You start by designing the printing layer for the inks to create the positive films. There is a layer each for the Phosphor, Dielectric, and Silver Inks. The designs will then be cast into Positive Films in-house or by a contractor.

Next is to get ready the screens. I recommend you do the screens in-house to control quality and cost. Due to the particle size and viscosity of the EL Inks, the mesh size and tension strength are different from normal printing inks. We recommend 100T-40 (250 mesh/inch) for all three inks and >20N/cm tensile strength for the screens.

Indium Tin Oxide Coated PET (ITO) is the most common substrate for screen printing EL. Cut the ITO to size according to the design.

The Phosphor Ink has to be put on a roller a few hours before printing, this is to ensure the Phosphor particles and the binder are homogeneous.

Now, you are ready to print.

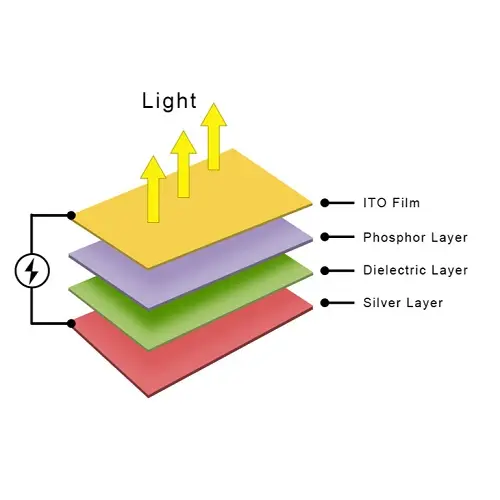

The EL Light Panel consists of several layers:

1. Transparent Conductive Layer: The first layer is the Transparent Conductive Layer, usually made of Indium Tin Oxide (ITO) coated PET film, which serves as the front electrode. Alternative conductive inks, such as PEDOT, may also be used.

2. Phosphor Ink Layer: The next layer consists of Phosphor Ink, which produces light when energized by high-frequency alternating current.

3. Dielectric Ink Layer: A dielectric ink is applied over the Phosphor Ink as an insulator.

4. Back Electrode Layer: To complete the circuit, a back electrode is printed using silver conductive ink, which is the most common choice.

5. Bus Bar: To enhance the conductivity of the front electrode, a bus bar printed with silver conductive ink is typically employed.

For the silk screen printing method, a mesh count of 100 (U.S. Mesh Count) is recommended for all inks. The suggested printing cycles are as follows:

1. Phosphor Ink: Print one pass and then send it for curing.

2. Dielectric Ink: Print one pass, cure, and repeat once.

3. Silver Ink & Bus Bar: Print one pass and send for curing.

Curing can be performed in a box oven at 130°C for 60 minutes or in a conveyor oven at 130°C for 4 minutes.

These guidelines are provided for reference only, and adjustments may be necessary to meet specific requirements.

Our team diligently updates content related to electroluminescent light technology to better serve you. However, please contact us with urgent questions before the updates are completed. We are always ready to assist you.

Stay updated with the latest in Electroluminescent Technology! Subscribe now for exclusive articles and insights.